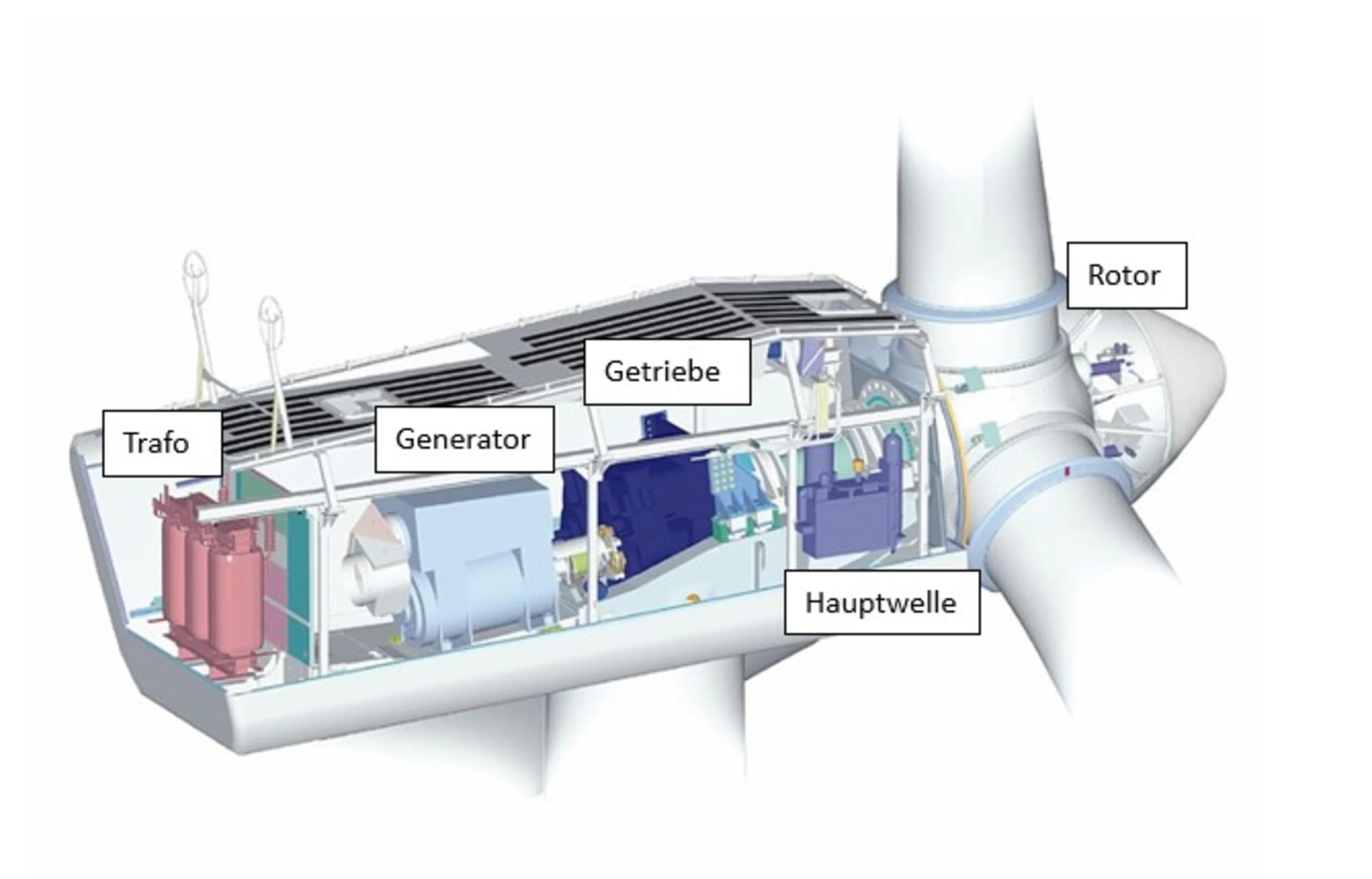

Gearbox:

We offer comprehensive services for gearboxes. We store HSS and IMS shafts and replace them when necessary. We carry out shaft repairs directly on the wind turbine and take care of gearbox suspension. In our workshop, we repair gearboxes and provide reports and repairs for planetary gearboxes. Additionally, we offer a complete oil service, conduct vibration analyses, and use endoscopy to inspect the condition of your gearbox.

Main Shaft:

We repair damaged bearing seats and replace bearings in our large components workshop. Whether you need to replace a main shaft or the entire drive train, we are here to assist you. Additionally, we perform endoscopies and oil analyses to assess the condition of your main shaft.

Generator:

We replace bearings and carry out repair work directly on the wind turbine. We also offer electrical measurements to ensure the functionality of your generator.

Transformer:

We conduct electrical measurements and replace transformers directly on the wind turbine. We can also perform minor repairs and replace pressure sensors on site.

Rotor Blade:

We measure and repair the lightning protection system on your rotor blades. We document damages and the work carried out in a rotor blade repair report. We support you with blade maintenance and inspection of bolted connections. Furthermore, we repair dismantled rotor blades on the ground and conduct maintenance and inspections on mounted rotor blades. This includes inspecting and repairing erosion protection and cleaning the blades when needed. Internal inspections and maintenance of mounted rotor blades are also part of our service.